I. What is Salt Spray Test?

Salt spray test is an environmental test that artificially simulates salt fog conditions to assess the corrosion resistance of products or metal materials. It is divided into two major categories: one is natural environmental exposure tests, and the other is artificial accelerated simulation salt fog environment tests. Testing a sample in a natural exposure environment takes a long time and is inefficient; whereas, testing under artificial simulated salt fog conditions can quickly yield results.

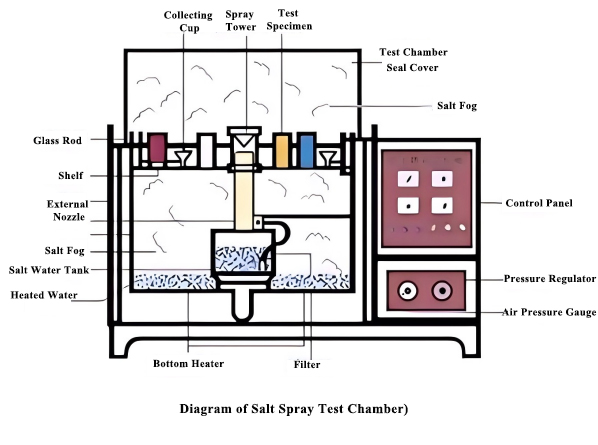

II. Principle of Salt Spray Test:

Most corrosion of metal materials occurs in the atmospheric environment, which contains oxygen, humidity, pollutants, and other corrosive components or factors. Salt fog corrosion is a common and most destructive form of atmospheric corrosion.

The corrosion of metal materials by salt fog mainly involves the penetration of conductive salt solutions into the metal interior to undergo electrochemical reactions, forming a "low potential metal - electrolyte solution - high potential impurity" microbattery system, with electron transfer occurring. The metal acting as the anode dissolves, forming new compounds, i.e., corrosives. Chloride ions play the main role in the salt fog corrosion process; they easily penetrate the metal oxide layer into the metal interior, destroying the metal's passive state. At the same time, chloride ions have a very low hydration energy and are easily adsorbed on the metal surface, causing damage to the metal.

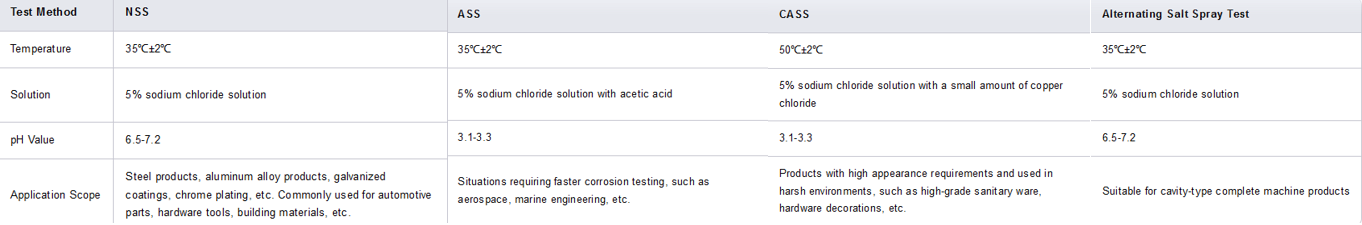

III. Artificial Simulated Salt Spray Tests are Divided into 4 Categories:

1. Neutral Salt Spray Test (NSS)

This is the earliest and most widely used accelerated corrosion test method. It uses a 5% sodium chloride salt solution, with the solution pH adjusted to the neutral range (6~7) for use as a spray solution.

2. Acetic Acid Salt Spray Test (ASS)

Developed based on the neutral salt spray test, it adds some glacial acetic acid to the 5% sodium chloride solution, reducing the solution's pH to around 3, making the solution acidic, and thus the salt fog also changes from neutral to acidic. Its corrosion rate is about 3 times faster than the NSS test.

3. Copper Salt Accelerated Acetic Acid Salt Spray Test (CASS)

This is a rapid salt fog corrosion test, with a small amount of copper salt—copper chloride—added to the salt solution, strongly inducing corrosion. Its corrosion rate is about 8 times that of the NSS test.

4. Alternating Salt Spray Test

This is a combination of neutral salt spray test and constant humidity and heat test. It is mainly used for cavity-type complete machines, allowing the penetration of humid environments so that salt fog corrosion occurs not only on the product surface but also inside the product. It involves alternating the product between salt fog and humid heat conditions to assess any changes in the overall machine's electrical and mechanical properties.

Comparison of the 4 types of salt spray tests is shown in the figure below:

IV. Determination Methods for Salt Spray Test:

The determination methods for salt spray test results mainly include grading determination, weight determination, corrosion occurrence determination, and corrosion data statistical analysis.

1. Grading Determination

Grading determination divides the percentage of corrosion area to total area into several levels according to a certain method, using a certain level as the basis for qualification judgment. It is suitable for evaluating flat samples.

2. Weight Determination

Weight determination involves weighing the sample before and after the corrosion test to calculate the weight loss due to corrosion, thereby judging the sample's corrosion resistance quality. It is particularly suitable for assessing the corrosion resistance quality of certain metals.

3. Corrosion Occurrence Determination

Corrosion occurrence determination is a qualitative determination method. After the salt spray corrosion test, the sample is observed for any corrosion to make a judgment, and this method is mostly used in product standards.

4. Corrosion Data Statistical Analysis Method

The corrosion data statistical analysis method provides for the design of corrosion tests, analysis of corrosion data, and determination of corrosion data. It is mainly used for analyzing and statistically assessing corrosion conditions, rather than for the quality judgment of a specific product.

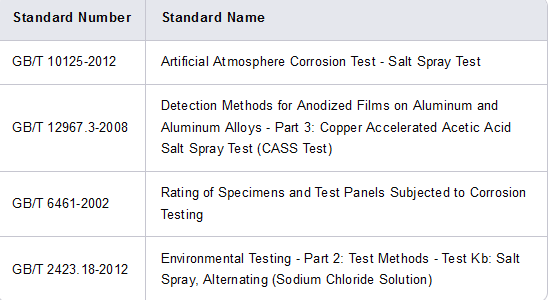

V. Execution Standards for Salt Spray Test:

Author: Quality Manager Ji

December 26, 2024