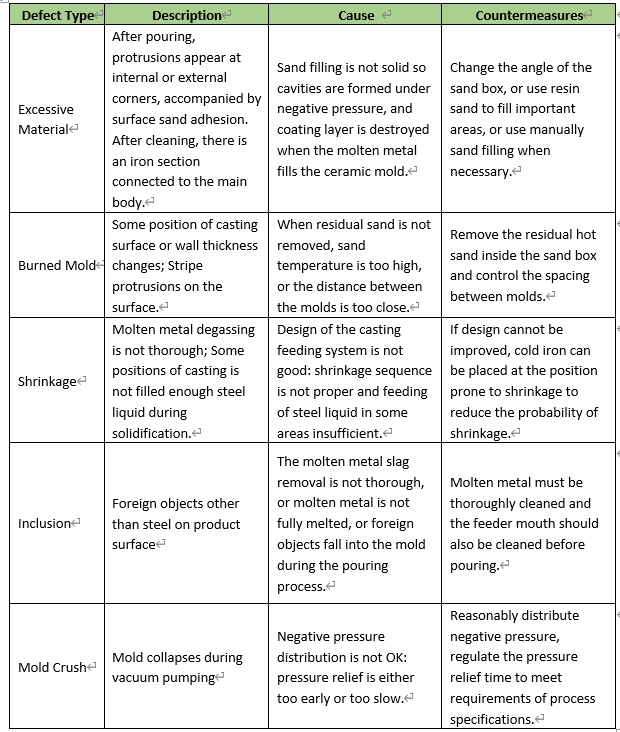

Although the lost foam casting process has many advantages, still there are process quality defects. Here lists the casting defects, their causes and countermeasures:

Lost foam casting may also have defects such as decarburization, wrinkling, dense porosity and slag inclusion. For example, dense porosity exists in the subcutaneous tissue of the casting, which can be discovered after the casting surface is machined, leading to a large number of castings being scrapped.

Another common defect in lost foam casting is slag inclusion, mainly due to dry sand grains, coatings, and other impurities entering the casting along with molten metal during the pouring process. These defects may be closely related to factors such as paint peeling and cracking on the white mold surface of the pouring system, the paint peeling at the junction, the runner gating system not being tightly closed, and the selection of process parameters.

Although lost foam casting process has the characteristics of high precision and excellent surface quality, various potential defects still need to be paid attention to in the actual process, and corresponding prevention and resolution measures should be taken. Controlling key process parameters and strictly following the process operation instructions by operators directly determine the quality of the castings produced.

Wang Bo

December 30, 2024